Design and development

It is known that designing and development takes up a significant chunk of time for car manufacturers looking to innovate and earn a competitive advantage. The design engineers are responsible for many tasks that start from conceptualizing to simulation and execution, and they always have to be on their toes to ensure optimum results. But AI can prove to be the game-changer here too.

For example, NVIDIA released its Quatro RTX graphics card powered by

NVIDIA Turing™, designed to accelerate workflows. It uses AI ray tracing and programmable shading to reinvent how we see product designing in the automotive sector.

Driver Behavior Analytics

The inculcation of IoT sensors has had a tremendous impact on understanding and decoding driver behavior. In addition, AI and deep learning-based software's inculcation in the automotive industry has meant that car manufacturers can now bring about solutions to improve overall driver efficiency.

For this, IoT sensors are placed on board to analyze the driver's behavior throughout the journey. In addition, these can also act as early warning signals and take the requisite steps to eliminate potential distractions or bottlenecks. Furthermore, ML is deployed to continuously track driver responsiveness and use a signal to alert the driver of their abnormal behavior and its potential impact on the vehicle.

Driver monitoring system

With AI in the mix, the system can automatically detect the driver's presence and make the requisite adjustments, such as mirrors, temperature, and seats. Furthermore, the software continuously detects the driver and their behavioral attributes, such as eye openness, head position, and more, to figure out if they are feeling drowsy and take steps to prevent any fatal damage to the vehicle.

Even in case an accident takes place. The AI chops can also adjust airbags according to the body's position. In addition, the presence of an AI system has allowed the inculcation of gesture navigation which has allowed the drivers to manage infotainment merely by gestures.

Emission monitoring

With the AQI (Air Quality Index) of several cities in the world already beyond alarming levels, there is a drive to control or improve automotive emission levels and reduce the overall carbon footprint. AI and ML can lead to a major turnaround for the vehicle industry.

As per a BCG

study, applying AI to corporate sustainability can increase savings and revenue to the tune of USD 1.3 trillion to USD 2.6 trillion by 2030.

It would require vehicle companies to employ AI-powered data engineering that helps in automated emission tracking. It can also collect data from several operational activities throughout the value chain. It can also source data from other sources, such as satellites, layer them up to find missing data, and undertake meaningful emission monitoring actions.

Fleet monitoring system

It is needless to state that AI can collate a multitude of complex data to figure out patterns beyond the periphery of a normal human brain. AI automatically breaks big data into actionable insights via digestible reports and visually appealing dashboards. It uses camera vision and advanced data, such as driver behavior and environmental conditions, to automate and augment the decision-making process regarding fleet management.

Generative designs

Modern-day vehicles are engineering marvels and require a lot of sophistication. So engineering companies are quickly adopting generative designs to help them develop highly-optimized vehicles. They leverage AI and ML to break down complex engineering processes and train these software to curate optimized designs based on certain parameters.

These work in partnership with other techs, such as 3D printing, to undertake rapid prototyping and mass customization. The adoption of generative design can have myriad benefits for car manufacturers. For example, General Motors used it to reduce the weight of their vehicles.

In-car voice assistant

Alexa has become an integral part of our homes. Similarly, the voice assistant is slowly becoming a vital addition to cars and other vehicles. While general intelligent assistants inform us about the topics we require them to, in-car voice assistants use sensors to monitor blind spots and assist the driver in steering, pedestrian, and obstacle detection. These real-time updates can help curtail unwanted road accidents and enable drivers to be more proactive than reactive.

Marketing

Scalability and precision are the two primary reasons car manufacturers are increasingly adopting AI for their marketing. Automotive manufacturers can undertake smart targeting with AI in the mix that uses historical data and predictive analytics for optimum results. In addition, it can also help you with your targeting and re-targeting endeavors that would help you level up your marketing without overspending on resources.

Predictive Vehicle Maintenance

A

study by McKinsey states that AI's strongest suit is its ability to inspect automotive parts and products over time, enabling its ML algorithms to get stronger in identifying shortcomings over time. In the 20th century and even in the first 15 years into the 21st century, automotive maintenance was more preventive than predictive.

We would do our guesswork and calculate a suitable time for an overhaul accordingly. But with AI and ML working in tandem, we are shifting towards predictive maintenance. The AI-powered software can provide the user actionable insights about the vehicle and its maintenance in real-time. It uses many data points to alert users timely, thereby improving vehicle availability efficiency and reducing depreciation.

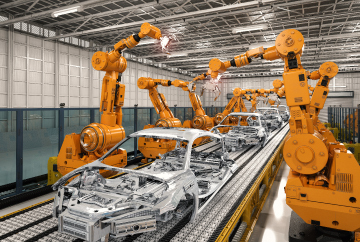

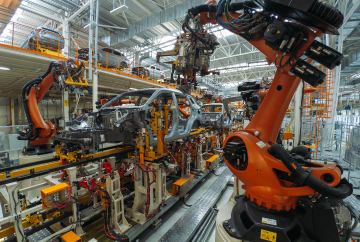

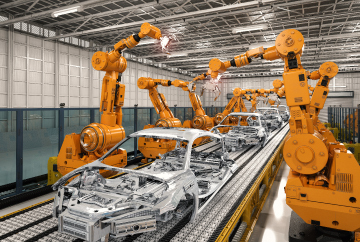

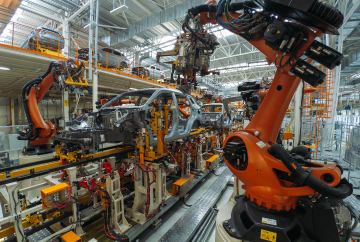

Manufacturing Process optimization

AI is not only changing the way vehicles are built but is also changing the entire development process. With the increase of

IoT and the massive adoption of AI to highly-critical tasks, we are already experiencing how it leads to

manufacturing process optimization.

Its predictive abilities help reduce equipment failure; robotics and human collaboration automate tedious processes and enable humans to focus on strategic tasks and computer vision leading to reduced quality control issues. In addition, it leads to more intelligent project management led by a leaner supply chain and improved business support functions for holistic improvement of the entire process.

Quality control

The traditional machine vision systems quickly pointed out structural scheme issues but weren't capable enough to trace abnormality during the production process. It led to the process being handed over to humans who relied on their expertise and experience to point out issues.

But the, modern workplaces quickly realize ML's abilities and employ them in conjunction with automotive safety. They also use deep learning to enhance quality control, tracking further and checking 100% of their products instead of going the sampling way.

Route optimization

The ability of AI to fiddle with big data and process a multitude of data seamlessly impacts route optimization for car manufacturers. It brings about last-mile efficiency, which uses trip sheets and real-time statistics to calculate the approximate time for covering a route.

In addition, big data enables the usage of spatial information that considers a plethora of factors to suggest the best ways while managing inventory and other critical needs. If implemented properly, route optimization can save tonnes of money and time, which is invaluable for the automotive and logistics industries.

Supply chain optimization

The supply chain was more straightforward back in the day. Today, the process has become far more complex with increased interlinking, making it difficult for humans to handle it manually. Further, the pandemic has increased volatility and a renewed focus on sustainability, forcing people to rethink supply chain optimization and resilience.

With

AI in the mix, there is a drive to transform the supply chain, and car manufacturers see many benefits, with improved decision making and visibility leading the roost. The AI-powered

supply chain will utilize cognitive predictions and recommendations to improve performance and is expected to power modern-day enterprises. In addition, ML can help them understand potential shortcomings and room for optimizations, thereby allowing them to embark on holistic improvement.

Vehicle prototyping

Like any other industry, the automotive industry suffers from cut-throat competition that necessitates rapid prototyping. But creating rapid prototypes that are not functional would not be feasible for car manufacturers. The new-age AI-powered prototyping uses innovative product development processes that eliminate several pain points present in the traditional prototyping and streamlines the entire process.

The usage of AI enables better CAD rendering and improves the prefabrication efficiency. In addition, it also helps enhance the quality of the product by allowing ML to point out design anomalies while supercharging the simulation process. In addition, artificial intelligence also helps automate repetitive tasks, enabling designers to focus on the more critical tasks.

Video analytics for shop floor

It took time for the world to realize that video analytics can have many more use cases extending far beyond mere surveillance and security purposes. The modern surveillance systems are integrated with computer vision, enabling them to make smart decisions. One such exciting use case for the retail sector would be to automate shop floor management, given that it is a repetitive task, but tedious presently.

For this, AI systems have transformed data into operable entities by assigning intelligent attributes. The algorithm can undertake data segmentation and establish patterns from the derived data sets. These use real-time feed and historical data to understand ideal behavior and violations and devise an optimum floor plan that would work in the best interest of automotive dealers.

Warehouse sorting

The automotive industry has been relentless when it comes to achieving operational efficiency. But with so much data in hand, warehouse management inadvertently became a significant pain point for many car manufacturers.

The inculcation of robots in the warehouse has enabled them to automate a considerable part of the

logistics network where these machines can track, lift, and sort items. It has allowed humans to focus on the more critical processes and seamlessly excel at warehouse sorting. It has also helped them reduce costs while improving quality control, contributing to manufacturers' improved customer experience and profit margins.