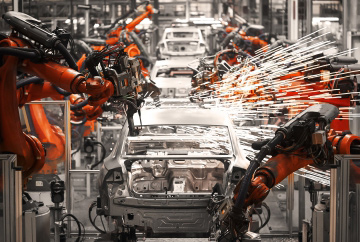

Impact of Industry 4.0 In Automotive Manufacturing

End Outcomes

Flexibility

The digital shift has caused a major shift in consumer expectations—flexible and agile top the game today. Consumers are looking for flexible solutions instead of committing to large-scale investments in this fast-moving world. Industry 4.0 adoption has made processes and operations more flexible in the automotive industry.

Efficiency

Automakers are looking to be more efficient. Hence, adopting the Industry 4.0 practices seem to be the best way to go. Assembly process optimization with AR images of vehicle chunks or technical information, making operations cost-efficient by prototyping and reducing design price. In addition, AR-guided warehouse location detectors, automated processes for storing parts, and product development induce productivity.

Agility

Higher demand for production requires the implementation of digital twins, automation, programmable bots, and predictive analytics.

Industry 4.0 practices are agile can be configured easily with minimal human intervention.

Click to zoom in

Value Chain Outcomes

Product R&D innovation

The winner takes it all! When visibility matters a lot, innovation comes to the rescue. OEM and vehicle manufacturers can leverage 4.0 to innovate design, framework, process flows, and practices to stay ahead of the curve.

Demand/Supply planning

Predictive Analytics

demand forecasting is implemented across the industry and proves beneficial. The automakers are now well-equipped to withstand a sudden spike in demand or an

inventory accumulation.

Shop floor operations

As there is a growing inclination towards AI, ML, IoT, and automation, operations are connected even without WiFi and appropriate infrastructure. Track and trace functionality enabled for detecting the movement of parts and equipment. Significant information exchange with the help of the digital twin and blockchain technology.

Supply chain optimization

Industry 4.0 induces

supply chain 4.0. With industries and production getting more localized, manufacturers are redesigning their supply chain implementing best practices and emerging technology.

Aftermarket sales

Industry 4.0 capabilities provide a major boost to customer support and services, field service operations helping manufacturers to deliver a uniform aftermarket experience. This, in turn, improves the dealer's responsiveness while curbing the vehicle downtime.

Sales and marketing

Processing customer inquiries, generating quality prospects, automation of contact centers, incorporating AI and process automation in different walks of marketing, processing account sheets, and more for smoother process operations.

Workplace Safety

As mentioned at the beginning of the article, implementation of bots, AI, and process automation fine-tune the different aspects of the work environment, ensuring safe and sound production.

Examples of Industry 4.0 in Automotive Manufacturing

Top of the lot automotive names today adhere to best Industry 4.0 practices to stay above the competition and lead the market.

BMW has an all-equipped, best-in-class Additive Manufacturing Center in Munich and professes that the company has recognized the technology for over 28 years. The automaker giant has 100,000+ precision components developed and manufactured every year, from prototypes to intricate plastic mountings and complex metal chassis parts.

Jaguar Land Rover has resorted to a closed-loop manufacturing process, developed with Dimensional Control Systems. The process involves actual and accurate measurements of the assembly process with the help of precursor CAD analysis and simulation tools. Furthermore, Mercedes promotes its 'Factory 56' concept, intending to equip its employees with Personal Digital Assistants (PDAs) and other digital tools. This will enable visualization of the production processes and optimized virtual reality to enhance accuracy and precision and enhance vehicle quality and speed.

Maruti Suzuki, the numero uno for customer support and service for over a decade, adheres to their "

Market to One" approach, which is the main reason behind customer retention policy. This approach brings all the elements to create a personalized experience for each of its customers, which has paid the brand off with an overall 3% growth in the first few months of adopting the strategy. The technology backbone of this concept was the powerful SAS, a software suite for advanced data analytics, creating a 360-degree view of the requirements of more than 10 million customers.