IoT and Blockchain: The Next-Gen Power Combo for Pharma Cold Chain

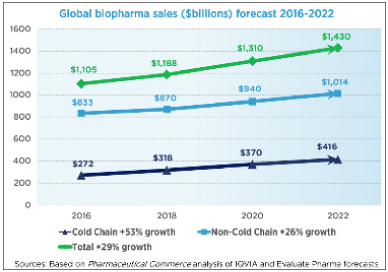

Cold chain logistics play a critical role in the safe delivery of perishable goods, pharmaceuticals, chemicals, etc. It is the backbone of a rapidly evolving pharmaceuticals industry. According to Pharmaceutical Commerce, the global cold chain and biopharma drug sales is forecasted to hit $416 billion by 2022—a 31% growth since 2018. It outpaces the non cold chain growth, which is 17% during the same time frame.

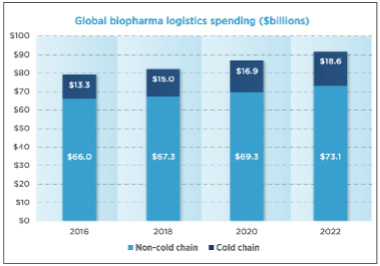

Added to this, the worldwide cold chain logistics spending is expected to reach $18.6 billion by 2022—up from $15billion in 2018.

These numbers indicate that cold chain logistics – pharma’s major component – need modernized systems that help preserve the quality of temperature-sensitive products.

Operational Challenges

Perishable, temperature-sensitive items are often very expensive to produce, limited in quantity, and need to reach their destinations in a specific time frame. In order to maintain their desired quality, these items are kept in safe environments, and within predefined temperature ranges. However, due to possible errors and gaps in monitoring and logistical problems, like an aircraft getting delayed on a hot tarmac, this is an area where pharma companies face the risk of very high cost product losses.

A failed cold chain poses a severe threat to patients by introducing the risk of delivery delays due to re-shipping products that have experienced environmental excursions. And at worst, by delivering unsafe products with undetected excursions. To ensure a seamless and efficient supply of products, it is essential to set up a robust system that delivers near-real-time insights and alerts across the end-to-end cold chain workflow.

Let’s dive right in to shed some clarity on this.

Need of the Hour: A Seamless, Transparent Cold Chain System

A robust, end-to-end cold chain system can be made readily available for pharma companies. It should include features/capabilities such as:

(i) A digitally integrated, transportation network designed for time-critical logistics

(ii) Automated data analysis of fastest origin/destination routes, considering real-time traffic conditions across road, rail, sea and air routes

(iii) Historical and near-real-time visibility and alerting of threshold excursions

(iv) A live map displaying continuous tracking and tracing of shipment status

(v) Geofencing capabilities that send shipment proximity alerts

(vi) Timely notifications that alert any potential delays

(vi) Automated verification/proof of shipments being picked up and delivered

(ii) Automated data analysis of fastest origin/destination routes, considering real-time traffic conditions across road, rail, sea and air routes

(iii) Historical and near-real-time visibility and alerting of threshold excursions

(iv) A live map displaying continuous tracking and tracing of shipment status

(v) Geofencing capabilities that send shipment proximity alerts

(vi) Timely notifications that alert any potential delays

(vi) Automated verification/proof of shipments being picked up and delivered

To enable these capabilities, it is important to integrate appropriate enhanced tracking and data transmission technologies on the cold chain landscape. Radio frequency identification (RFID) technology, for instance, can provide tracking data that can be used to optimize business processes, upgrade automation levels, and eliminate bottlenecks. However, RFID is generally only useful for tracking items within the four walls of the plant and can be cost-prohibitive. In many cases, within the plant, the existing wifi network or Bluetooth Low Emission (BLE) can be deployed more cost-effectively. Across the external global supply chain, other technologies must be considered, such as cellular and satellite, and when there is no option for a live data uplink, data logging.

Having said that, there is a growing need to adopt leading technologies such as the Internet of Things (IoT) and Blockchain in pharma. These technologies enable the above-mentioned features/capabilities. When implemented, they can fill the existing gaps in pharma while significantly improving cold chain logistics.

Let’s focus on how each one of these technologies can contribute towards an efficient cold chain.

The Internet of Things (IoT): A Smart Ecosystem of Sensors

IoT sensors play a vital role in the cold chain in terms of capturing and transmitting environmental monitoring data and analyzing transportation routes, proximity alerting, damage control, etc. These sensors provide real-time visibility and send alerts from time to time. They can also help improve the safety of pharmaceutical products by eliminating threats caused by human errors, enhancing real-time transparency.

As a result of these capabilities, IoT helps prevent costs associated with loss of products rejected due to low-quality standards.

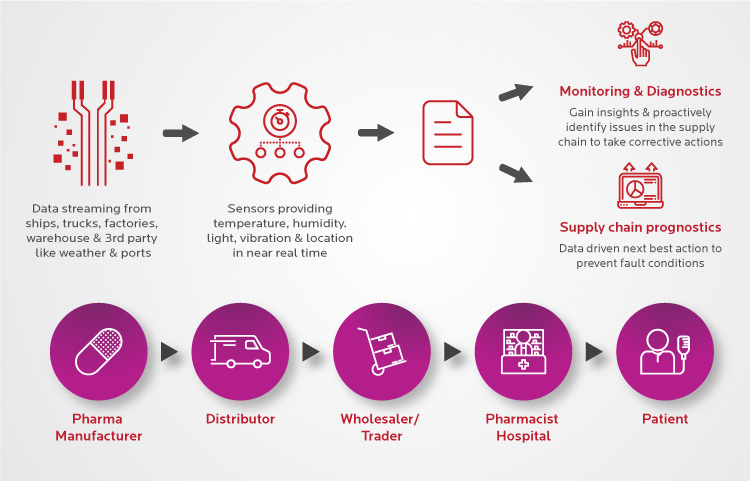

An IoT-powered cold chain workflow

Pharma products, once picked up from manufacturing units, travel through different modes of transport. Inevitably, they may be subject to varying environmental conditions where variables, including temperature, humidity, vibration, light exposure, and orientation, need to be monitored. Utmost care is taken to store these consignments within the prescribed environmental setpoints, however despite best plans and precautions, there may arise variations outside of acceptable tolerances, or excursions, that can’t be ruled out during transit.

In such a scenario, IoT can provide real-time data to pharma companies on every step of the transit, with enhanced visibility. IoT sensors will immediately notify of any temperature variations or damages caused to the products. Later, companies can determine whether their products meet the required quality standards to enter the market, or if the products must be returned for destruction.